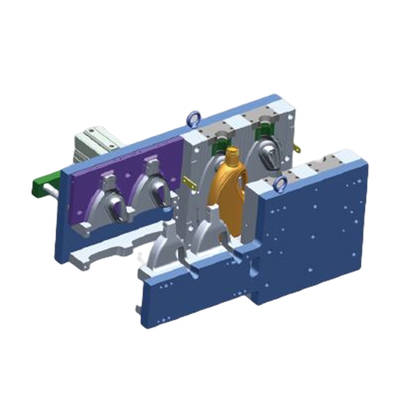

The tubular plastic parison obtained by extrusion or injection molding of thermoplastic resin is placed in a split mold while it is hot (or heated to a softened state), and compressed air is introduced into the parison immediately after closing the mold to blow the plastic parison. It expands and sticks closely to the inner wall of the mold, and after cooling and demoulding, various hollow products are obtained.

Extrusion blow molding is a method of making hollow thermoplastic parts. Well-known blow molding objects are bottles, barrels, cans, boxes and all containers for packaging food, beverages, cosmetics, pharmaceuticals and daily necessities. Large blow-molded containers are commonly used for packaging of chemicals, lubricants and bulk materials. Other blow molded products include balls, bellows and toys. For the automotive industry, fuel tanks, car shock absorbers, seat backs, center brackets, as well as armrest and headrest covers are blow molded.

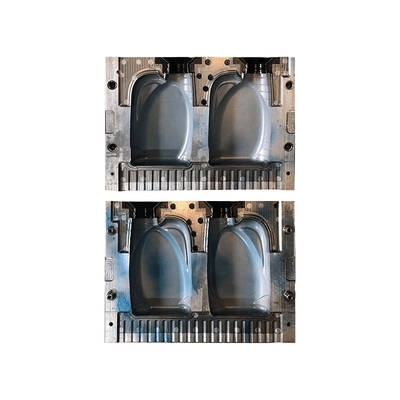

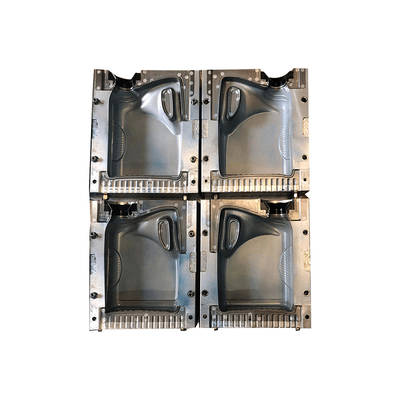

Bottle molds are various molds and tools used in industrial production to obtain the desired products by injection molding, blow molding, extrusion, die casting or forging, smelting, stamping and other methods. It plays a key role in the production process. The number of cavities in the bottle mold determines the production efficiency. According to customer needs, the corresponding molds are produced.

Mold production materials: zinc alloy Cr12, Cr12MoV, S-136, SLD, NAK80, GCr15, T8, T10, aluminum alloy, copper alloy 5CrMnMo, 3Cr2W8, 9CrSi, W18Cr4V, 5CrNiMo, W6Mo5Cr4V2, M2, aluminum alloy, copper alloy, Steel Titanium GH130, GH33, GH37, Titanium Alloy, Steel, Stainless Steel, Nickel Alloy K3, K5, K17, K19, GH99, IN100, ЖC-6NX88, MAR-M200, TRW-NASA, WA. Change the material according to the customer's needs and usage.

Plastics suitable for blow molding include polyethylene, polyvinyl chloride, polypropylene, polyester, etc.

If you have any questions, please feel free to contact.

Taizhou Shunke Moulding Co., Ltd is

China Bottle Mold Manufacturers and

water Bottle Mould Factory. We specialized in designing and manufacturing plastic cap mold, PET preform mold, blowing mold with our own mould factory. When we get samples or drawing of product, we always make all round analysis and inspection, such as moulding process feasibility, mould structure and movement feasibility, all the related plastic components matching situation, etc. We offer solution and custom make Bottle Mould, other services.

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More