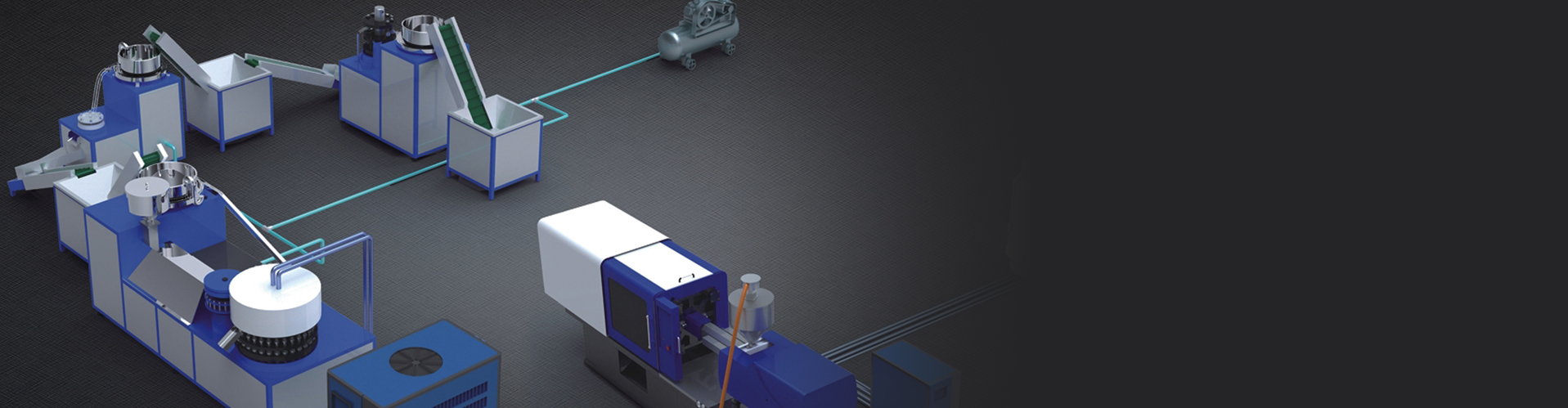

3L 2 Cavity Blow Moulding Machine

Features:

1. Adopt special electronic controlling circuit for heating, high efficiency in simultaneous controlling one lamp or more, lower power consumption.

2. Adopt the theory of heat transfer and feedback while designing the shape and thickness of preform.

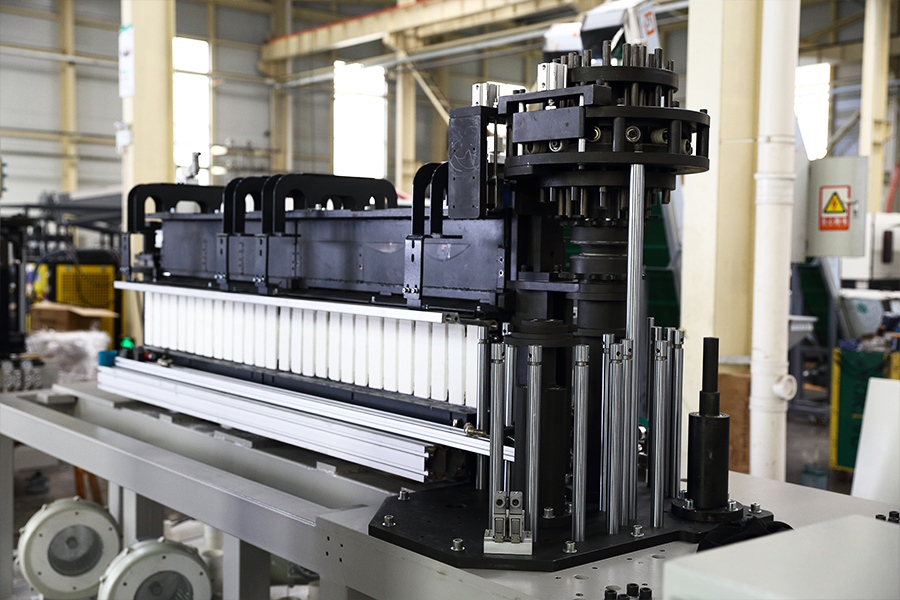

3. The preform will be heated evenly, not be influenced by outside environment.

4. Cooling system with cold air cycle ensures same heat exposure of internal and external surface of the bottles.

5. Air circuit system consists of movement and blowing so as to meet the needs of different air pressure, also to provide the stable high pressure for blowing different shapes of big capacity bottles.

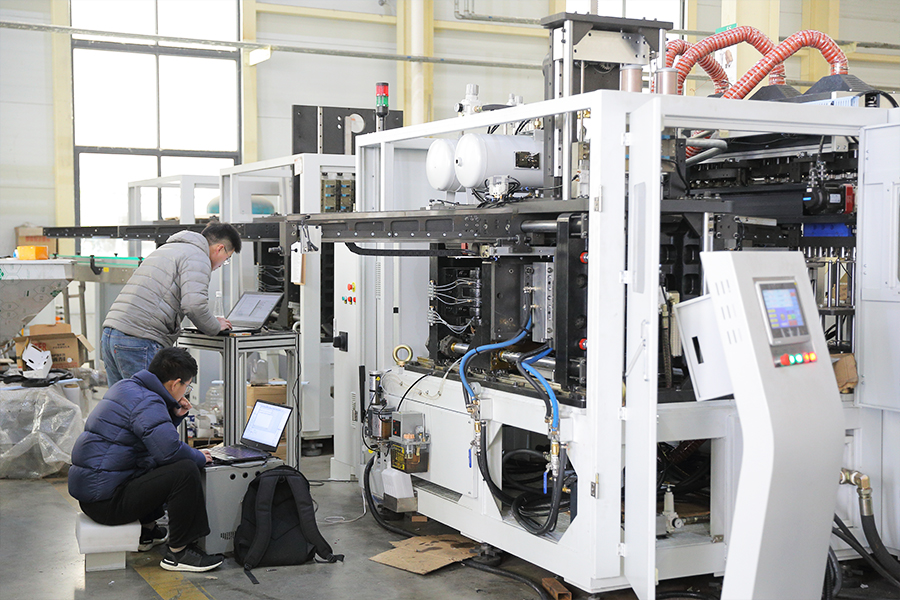

6. The system is equipped with silencer, connecting rod and articulated refueling devices.

7. Two modes of operations: semi-automatic mode and automatic mode.

8. Small size, low investment, one person enough to operate, simple and safe.

English

English русский

русский Español

Español عربى

عربى

+86-15157625901 / 13706572756

+86-15157625901 / 13706572756 info@suncomold.com

info@suncomold.com  No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China

No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China