Oil cap molds are very useful for many different things in your business. You may be wondering how these products can help you, and what they are used for. Basically, they have two major purposes; to create caps that fit into bottles, and to protect the caps from oil spills and corrosion so that they last much longer. The mold design tool is used to create the cap that fits tightly to the bottle, and has holes around the edges of the cap so that it can be closed as well. This allows the cap to prevent oil from spilling onto the surface of the bottle.

There are a few different kinds of these molds to choose from, depending on the project you are working on. Some oil cap molds are specially designed to be used in small and large products alike, making them very versatile. These cap molds are often seen being used in conjunction with other types of molds in order to speed up the creation of caps for products like pharmaceuticals or chemicals.

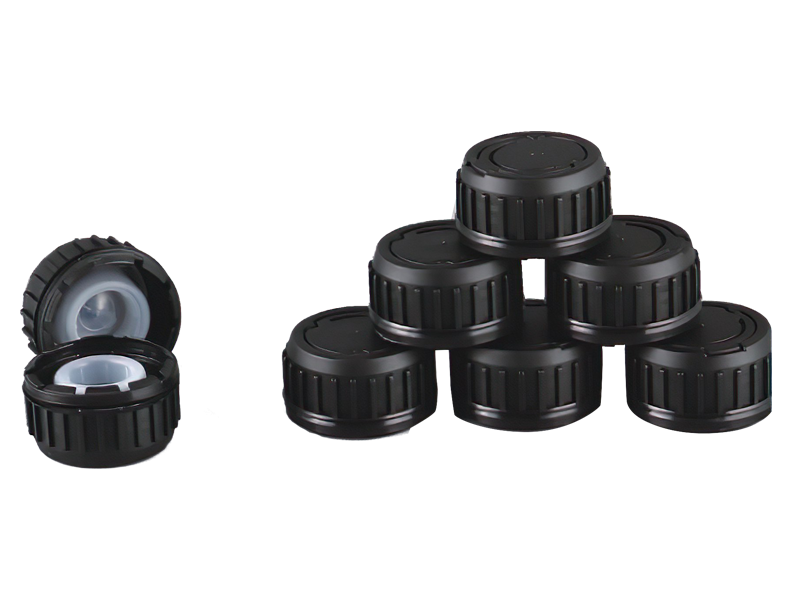

If you are someone who likes to do their own projects using molds, then you will find that there are a variety of different sizes and shapes available. The majority of these items are round, although you will find some designs that have a square or octagonal shape to them. As you are probably aware, when you put something in a round container, it will cover a larger surface area, which means that your product will come out smaller than if you had used a square or octagonal shaped container. However, with the oil cap moulds, because the product comes out clearer, you will see more surface area to work with, and therefore this can make your projects go much faster.

Another thing to keep in mind is that these moulds work great for lubricant oil caps. Because the cap is so constricted, it limits the amount of air that can flow through it, which means that the lubricant oil will not leak out of the cap, and instead remain contained within the mould. In turn, this means that you can use these oil cap moulds to make a range of different sizes of cap, all of which are going to be very effective. You will find that they are suitable for making small diameter caps, as well as elongated ones, and this means that you can choose the perfect cap for your application.

If you are also someone who likes to get things custom made, then you will find that the two color cap mold is a great option for you. Two color oil bottle cap molds are ideal for making labels for bottles that you are going to sell or use internally, and you will find that they are very easy to create. In fact, most people will agree that they are easier than any other type of product mould. You simply use two dye inks to decorate the cap, then place it in an appropriate container, such as a clear acrylic container, and it will turn out looking just like it is supposed to.

Finally, there is the hot runner oil cap mold. This is a high quality mould designed to be used in large applications. The benefit here is that they are going to have a high tolerance to heat, meaning that you can produce a large amount of items at once without any problems, and you will love the way they look when they are finished. You should note that when you are using a hot runner mold to make lubricant oil bottles, that you should ensure that you do not heat the metal beyond its melting point, because this will cause problems. In most cases, you should start off using a cold runner, because this helps to prevent excessive heating that can damage the material. When you are finished, you can add an acrylic veneer cap to the bottles and use them to store your lubricant oil.

English

English русский

русский Español

Español عربى

عربى

+86-15157625901 / 13706572756

+86-15157625901 / 13706572756 info@suncomold.com

info@suncomold.com  No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China

No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China