The PET Preform Survey is conducted by a multinational group of researchers who have extensive experience in the survey of this important industry. Their report " PET Survey of Growth in Asia and Middle East", published in May-June, 2021 in the Journal of Materials Science and Technology (JMT), provides a statistical analysis of world trade and investment in PET Preform. The report estimates that Asia and the Middle East will be the largest users of PET products, followed by Europe, North America, and Oceania. Asia and the Middle East are among the fastest growing consumer markets for PET, with China leading the way. While the overall global demand for PET is growing, Asia and the Middle East are experiencing a sharp growth in demand for PET as recycling rates increase in these countries.

High costs of production and import reduce profits for manufacturers of pet preform bottles. As a result, companies find it more cost-effective to source low-cost plastic from Asia and the Middle East where manufacturing processes and raw materials are lower. A number of Asian countries manufacture high quality raw materials needed to manufacture PET bottles. The major contributors to the Asia and the Middle East demand include China (PET bottles), India ( PET bottles and sheets) and Malaysia (plastics fertilizer and chemicals).

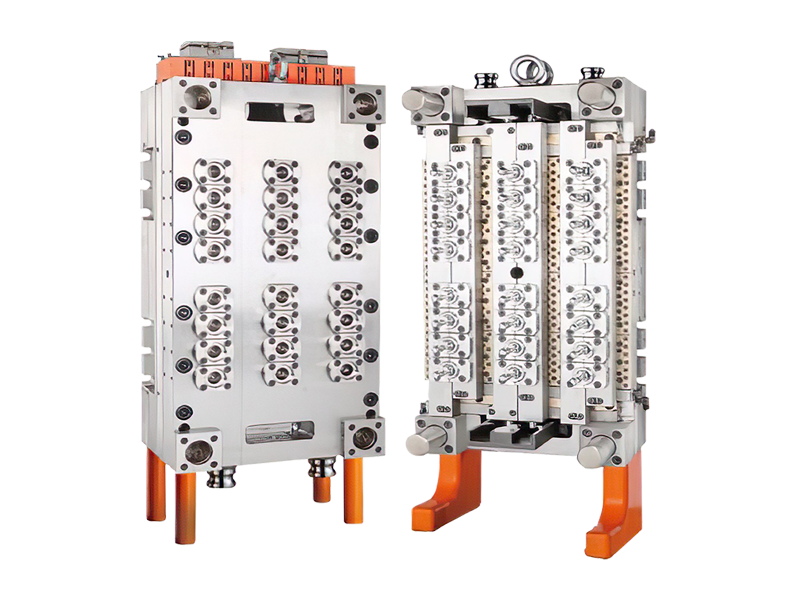

The primary factors influencing the demand are the high cost of PET bottles and the limited supply of pure PET. Injection molding of plastic requires high temperatures and pressure. High temperature injection molding of PET leads to significant energy usage due to the heating of the PET components and shrinking of the plastic bottles after injection into the molds. As a result, energy consumption increases and the price of PET continues to decrease.

Another major constraint in the supply of pet preform is the limited availability of certain polymers used in the process of injection molding of plastic. Polymers such as polyethylene terephthalate (PET esters) and polyethylene glycol (PET Glycol) are crucial to the process because they are required for the crystallization of the plastic bottles. Similarly, the limited availability of certain temperature-resistant plastic components is another important factor constraining the production of certain PET bottles. The limited availability of certain temperature-resistant materials results in the increased cost of production of pet preform.

To overcome these challenges, manufacturers of preform bottles have developed technology that allows PET bottles to be cooled using water or ice. This technology has been incorporated into the injection molding process to enable injection molding of plastic without heating the polymer components. The resulting bottles cool using gas cooling or water cooling systems.

A number of companies manufacture and deliver PET bottles that are well suited for use in injection moulding. It is important to choose a company that can customize a solution to your manufacturing requirements. If you are not able to meet the preform standards due to insufficient expertise in the industry, you may need to pay a higher cost to have a custom solution. However, most injection moulding companies are able to design solutions to meet the specifications that you provide. In addition, many offer training in the design and manufacture of preform injection moulds.

English

English русский

русский Español

Español عربى

عربى

+86-15157625901 / 13706572756

+86-15157625901 / 13706572756 info@suncomold.com

info@suncomold.com  No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China

No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China