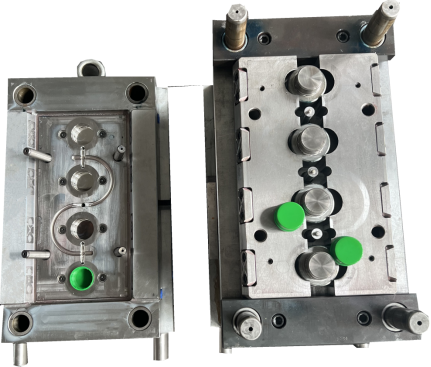

1:SK Mold Factory is a factory specializing in the manufacture of cap molds. We specialize in manufacturing all kinds of plastic cap molds.Food bottle cap mold, we can make water bottle cap mold, juice bottle cap mold, carbonated beverage mold. In the field of industrial use, we can also customize the oil cap mold. The picture shows the mold of the engine bottle cap. This mold is four cavity, cold runner, runner design is S-shaped, in the production of raw materials can be quickly filled with each cavity, so that the production of lid products uniform and good quality. The mold takes 10 seconds per injection and can produce 24 per minute. We can make molds according to customers' needs. The more cavities, the higher the output per minute.

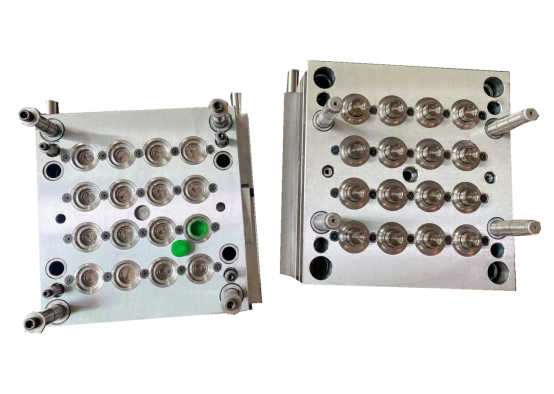

2:SK Mold Factory is a factory specializing in the manufacture of lid molds. We specialize in manufacturing all kinds of plastic cap molds.Food bottle cap mold, we can make water bottle cap mold, juice bottle cap mold, carbonated beverage mold. In the field of industrial use, we can also customize the oil cap mold. This is a four-cavity oil cap mold. Mold runner is cold runner, point gate. We used inserts for the main part of the mold core and cavity. After constant collision and wear, when the mold has certain damage, we replace the main insert, so that the mold can continue to use, which is also a way for us to extend the life. Our cover mold uses S136 steel material with a hardness of 55, which is also the way to ensure a long service life of the mold.

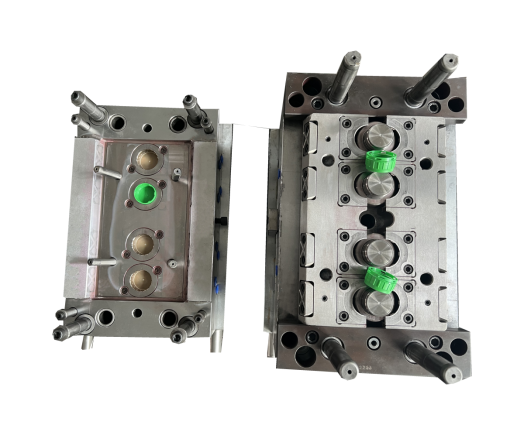

3. SK Mold Factory is a specialized cap mold factory in Zhejiang Province, China. We specialize in manufacturing all kinds of plastic injection cap mold. The mold in picture is a four-cavity oil bottle lid mold. Mold runner is cold runner, point gate. All the main part of the lid mold core and cavity, we use inserts in order to change easliy. After constant collision and wear, when the lid mold has certain damage, we replace the main insert, so that the lid mold can continue to use, which is also a way for us to extend the lid mold life. Our lid mold main part uses S136 steel material with a hardness of 55, which is also the way to ensure a long service life of the mold.

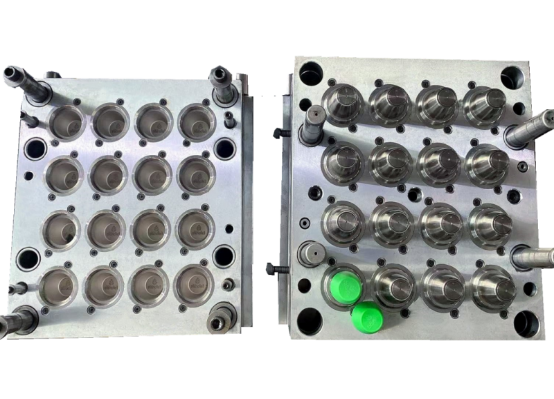

4. SK Mold Factory is a specialized cap mold factory in Zhejiang Province, China. We have more than 15 years experience to make all kinds of plastic injection cap mold. The mold in picture is engine oil bottle lid mold. Mold runner is cold runner, point gate. All the main part of the lid mold core and cavity, we use inserts in order to change easliy. Our lid mold main part uses S136 steel material with a hardness of HRC45-55, which is also the way to ensure a long service life of the mold. The mold base is P20, the material hardness is HRC30-30. Mold surface will via vacuum hardening, it can also enhance mold hardness. Normally, the mold life is five million shots. We can also make cap mold depend your samples.

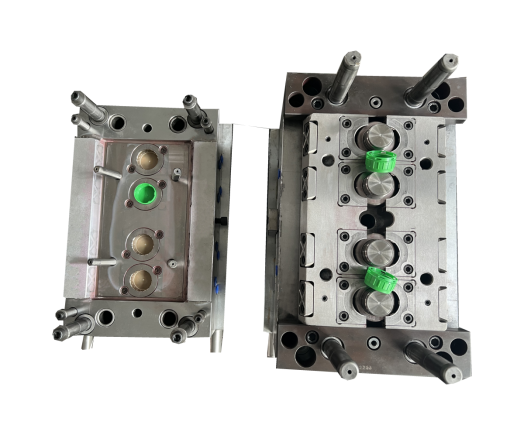

5. SK Mold Factory is a specialized cap mold factory in Zhejiang Province, China. We have more than 15 years experience to make all kinds of plastic injection cap mold. The mold in picture is engine oil bottle lid mold. Mold runner is cold runner, point gate. All the main part of the lid mold core and cavity, we use inserts in order to change easliy. Our lid mold main part uses S136 steel material with a hardness of HRC45-55, which is also the way to ensure a long service life of the mold. The mold base is P20, the material hardness is HRC30-30. Mold surface will via vacuum hardening, it can also enhance mold hardness. Normally, the mold life is three million shots. We can also make cap mold depend your samples.

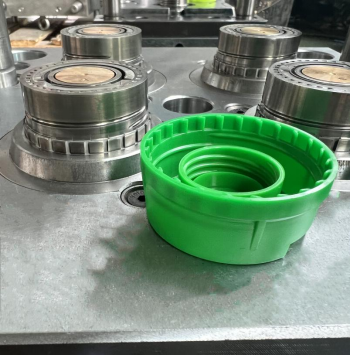

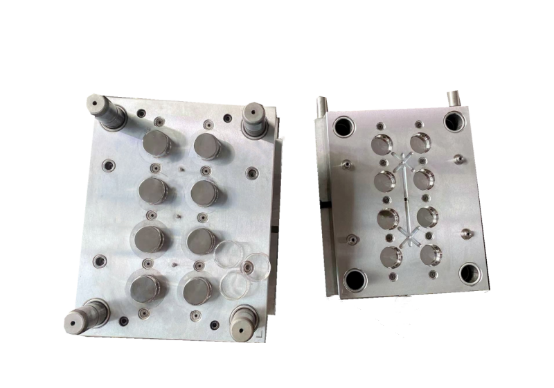

6. SK Mold Factory is a specialized cap mold factory in Zhejiang Province, China. We can customize all kinds of plastic injection cap mold. The mold in picture is 28mm protective outside cap. The cap mold is 16 cavity, cold runner, point gate. All the main part of the cap mold core and cavity, we use inserts in order to change easliy. Our cap mold main part uses S136 steel material with a hardness of HRC45-55, which is also the way to ensure a long service life of the mold. The mold base is P20, the material hardness is HRC30-30. Mold surface will via vacuum hardening, it can also enhance mold hardness. Normally, the mold life is three million shots. We can also make logo on the cap mold depend on customers’ demand.

7. SK Mold Factory is a specialized cap mold factory in Zhejiang Province, China.We can customize all kinds of plastic injection cap mold. The mold in picture is 37mm protective outside cap. The cap mold is 8 cavity, cold runner, point gate. The cap material is PC. Cap mold core and cavity, we use inserts in order to change easliy. And the surface of the cavity is polished to a very smooth finish. Our cap mold main part uses S136 steel material with a hardness of HRC45-55, which is also the way to ensure a long service life of the mold. The mold base is P20, the material hardness is HRC30-30. Cap mold surface will via vacuum hardening, it can also enhance cap mold hardness. It can also help to prolong the life of the cap mold.

English

English русский

русский Español

Español عربى

عربى

+86-15157625901 / 13706572756

+86-15157625901 / 13706572756 info@suncomold.com

info@suncomold.com  No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China

No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China