Injection mold factory introduces you to mold temperature control

Injection mold is a kind of thing that produces plastic products; it is also a thing that gives plastic products a complete structure and accurate standards. Injection molding is a processing method used in the mass production of certain complex-shaped parts. Specifically, it refers to the high-pressure injection of the heated and melted plastic into the mold cavity by the injection molding machine, and the molded product is obtained after cooling and solidification. The following is a detailed introduction to the classification of injection molds and the temperature control of the mold from the injection mold factory. I hope it can be helpful to everyone!

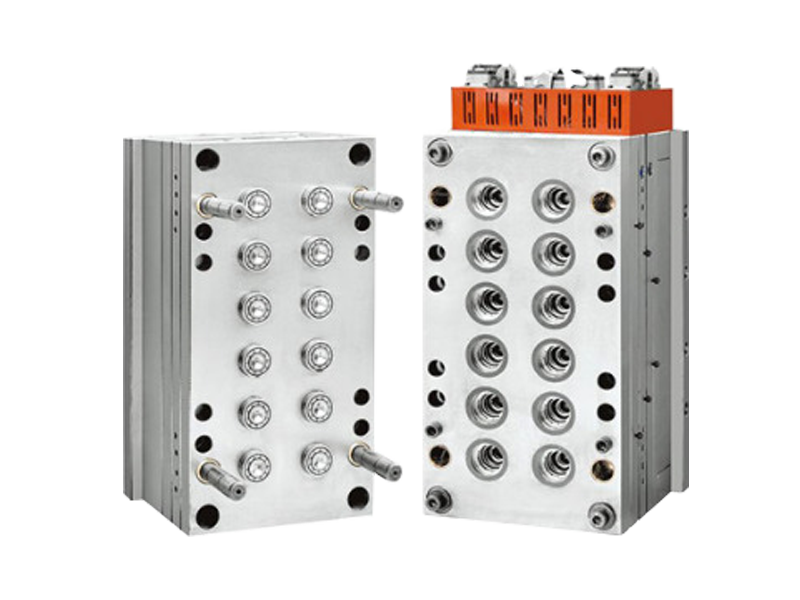

Injection molds are divided into thermosetting plastic molds and thermoplastic plastic molds according to the molding characteristics; according to the molding process, they are divided into transfer molds, blow molds, casting molds, thermoforming molds, hot press molds (compression molds), injection molds, etc. In the meantime, the hot press mold can be divided into three types: overflow type, semi-overflow type, and non-overflow type. The injection mold can be divided into two types: cold runner mold and warm runner mold by the gating system; according to the loading and unloading method It can be divided into two types: mobile type and fixed type.

There are three heat transfer methods: radiation, convection and conduction. In the mold, the heat generated by the plastic brought into the mold is 95% absorbed by the mold through conduction, and about 5% is emitted into the air by radiation and convection. During the processing, the change of temperature is a more important influencing factor, and it has a great impact on the quality of the product, and indirectly affects the production efficiency.

The mold temperature control method is to cool the mold with a liquid flowing in the cooling pipe. Since water is quite cheap, water is used as the primary coolant to cool the mold. The water can guide the mold to shorten the rapid cooling time. Generally colder molds are more useful because of faster production cycle times. However, this is not necessarily correct, because some materials are too cold to have a counterproductive effect. Generally, beryllium copper inserts are used in the mold to improve the cooling effect of the mold. The mold is not good for heat dissipation (such as the part wrapped around the plastic part). The beryllium copper material with excellent thermal conductivity can also quickly transfer heat to the flow through it. The cooling water takes away, thus reaching the cooling effect. There are also plastics with high melting temperature that require the mold to be heated for injection molding. For example, a resistance wire heating rod is used to inlay the mold base to heat the mold. The liquid used for mold cooling is water and oil; generally, there are 3 types of water, ice water, water plus antifreeze. Conversely, when the mold temperature needs to be increased, hot water is used to heat the mold.

/

English

English русский

русский Español

Español عربى

عربى

+86-15157625901 / 13706572756

+86-15157625901 / 13706572756 info@suncomold.com

info@suncomold.com  No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China

No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China