A good PET preform mould should be durable, have a high degree of functional strength, be competitively priced, and have practical characteristics. The plastics used in the mold should be matched with the appropriate steel and processes.

Besides, the preform mold must incorporate special finishing tools like buffing attachments, drilling jigs, and holding fixtures. Finally, the molding process should be accurate with the help of gages.

A good PET preform mold should have good structural strength, attractive appearance, and ease of use. It should also be cost-effective and offer excellent performance. It must also be equipped with appropriate finishing tools. These tools include gages, drilling jigs, and buffing attachments. Further, the molding process should be easy to operate. It must also be equipped with the right processes and steel. In addition, the mold should be designed using the correct processes and steel.

A good PET preform mould is durable. It should have high functional strength and sales appeal. In addition, it should be competitively priced. The design of a PET preform mold must have the most appropriate steel and processes.

Especially, a preform mould must have water cooling channels to minimize the overall cycle time. The process of water channeling should be done carefully, to eliminate the possibility of jamming. This feature should also be affordable.

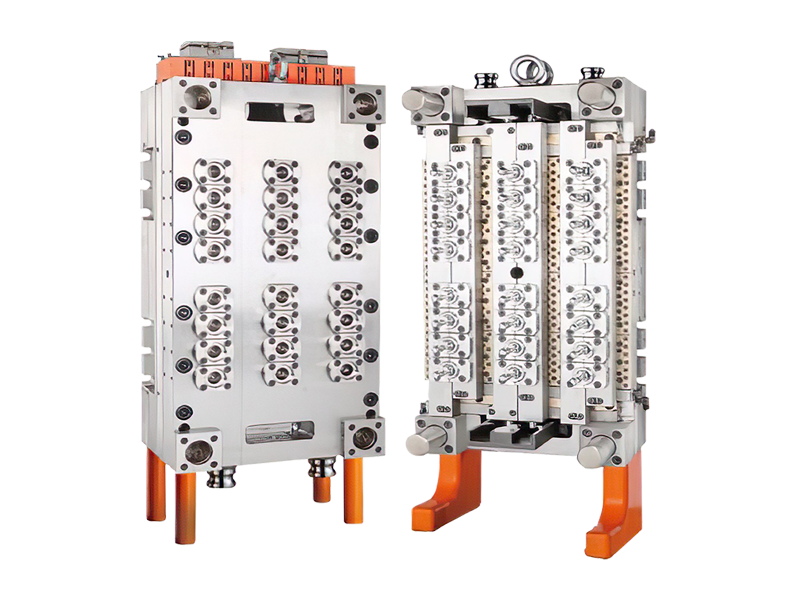

The design of a PET preform mould is an important part of the process. Its two halves are assembled together on mounting plates, which are drilled for air and cooling water. These two pieces are then fixed on the mould. During the process, both parts must be in alignment. A poorly designed PET preform will have poor performance and will be less transparent. Moreover, the quality of a preform is critical.

A high-performance PET preform mould is highly recommended for companies producing a lot of identical parts. If your requirements are flexible, a high-output mould is ideal for larger-scale production. For smaller batches, a low-output mold will serve the same purpose. Choosing the right size of a mold is equally important for both the quality of the product and the efficiency of the process. By choosing a suitable preform mould, you will be able to choose the smaller machine for production and save the production cost.

English

English русский

русский Español

Español عربى

عربى

+86-15157625901 / 13706572756

+86-15157625901 / 13706572756 info@suncomold.com

info@suncomold.com  No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China

No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China