A cap assembly machine is a piece of equipment that assembles plastic, metal, and beverage caps. It can assemble a wide variety of products and is perfect for a wide range of industries. Some of its key features include automatic orientation, automated tooling, and high-speed production. These machines are designed to handle different types of caps and can be used in industries ranging from food to chemical to beverage. They have been manufactured to ensure a smooth and consistent operation.

Cap closing machines are ideal for the assembly of flip-top closures and oil bottle caps. This machinery is typically controlled by a PLC. The system is a complete package, including safety devices to prevent a machine from operating without a cap in place. Its primary application is in the food and chemical industries.

Cap closing machines have been designed to be very safe. Safety devices, such as sensors to check the operation of each actuator, ensure that the machine does not operate if a cap is not in place. Depending on the type of product, a cap closing machine can be used inline, on a stand-alone base, or in combination with other equipment. Whether you need a stand-alone, in-line, or combination of machines, you can find one to meet your needs.

Cap wadding machines are manufactured with the highest quality substances and additives to provide excellent performance over the long term. Wadding machines are made to accommodate caps of various sizes, from 28mm to 174mm. Their design includes a sturdy, welded metallic frame that is enclosed in a stainless steel sheet. There are also models that incorporate doors for servicing the cap wadding system.

A rotary die tooling station is available in many of these machines. If you need additional punch die tooling for a specific product, you can easily upgrade your machine to include this capability. You can also purchase larger tools for more complex components.

Liner putting is another important step in cap assembly. These machines can be equipped with a vacuum liner taking device that removes liners from rolls for putting into the cap. They are also able to put liners into a wide range of cap sizes, from 28mm to 174mm.

The liner putting machine is a reliable tool, with high accuracy and efficiency. It is suitable for activities with strict sanitary requirements. Unlike other putting and lining systems, it omits manual painting, which is an environmentally harmful activity. As a result, this machine can be used for a variety of applications that require healthful and safe products.

These machines have the capability to assemble two or three caps automatically. Each cap is supplied with an indexing dial that moves it to predetermined areas. When it is time for a new cap, the machine takes the component from the feed conveyor and sends it to the dial.

A cap closing machine is a perfect addition to a cap factory. Besides the advantages mentioned above, it is also highly beneficial in the production of vinegar and oil bottle caps.

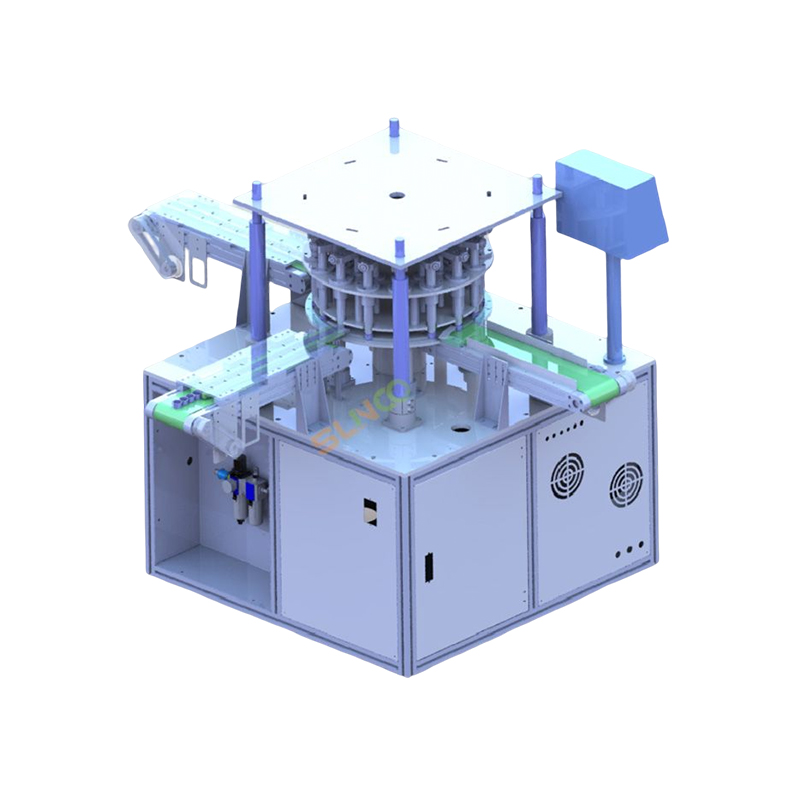

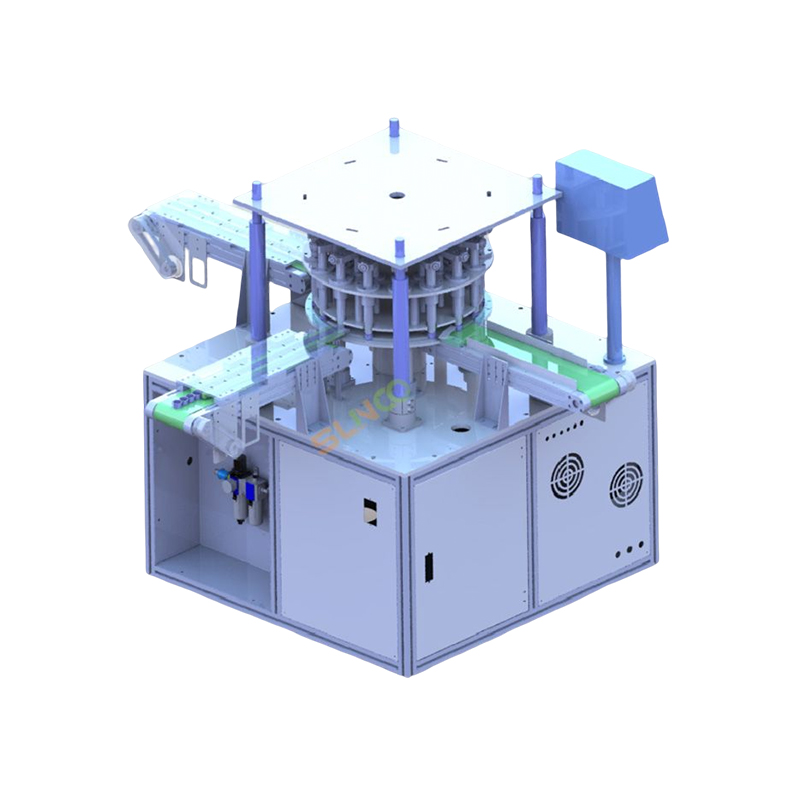

Cap Assembly Machine for push pull sport cap

Cap Assembly Machine for push pull sport cap

English

English русский

русский Español

Español عربى

عربى

+86-15157625901 / 13706572756

+86-15157625901 / 13706572756 info@suncomold.com

info@suncomold.com  No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China

No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China