PET bottles have strong applicability and are widely used in daily necessities, daily chemical packaging and other fields. From mold processing to machinery and equipment, they are very picky. It is easy to get started, but difficult to do well. PET preforms are reprocessed by blow molding to form plastic bottles, including bottles used for packaging cosmetics, medicines, beverages, mineral water, reagents, etc. Plastic processing to form PET plastic bottles.

The key factors for choosing PET preform injection molds are as follows:

1. Plastic materials: Different plastic materials have different processing variables, and those processing variables will affect the selection of the warm runner system.

2. The weight of the product: products with different weights have different requirements for the warm runner.

3. Nozzles: Nozzles can generally be distinguished by size, temperature distribution, physical properties, materials used (copper, steel, etc.), and the difficulty and price of maintenance.

4. Mold: What is the number of cavities? What is the nozzle distribution distance? What kind of material is processed? And so on, these are the mold elements related to the optional hot runner system.

5. Cycle cycle: Fast production cycle means the improvement of nozzle requirements. For example, nozzles must deliver heat accurately and be durable.

6. Gate: For the point gate, in order to maintain excellent thermal balance in each molding cycle, the tip of the warm flow nozzle must have the function of melting the material and cooling the seal. The valve gate uses a mechanical method to seal the gate.

7. Runner: The application of the warm runner system avoids the production of material handles, which not only saves materials, but also saves the previous process of removing material handles by hand, manipulator or other methods.

PET bottle preform is a typical injection molding product, which is easy to transport. It is mostly plastic raw material with uniform texture and excellent insulation. It is an important product for plastic bottles and oil barrels.

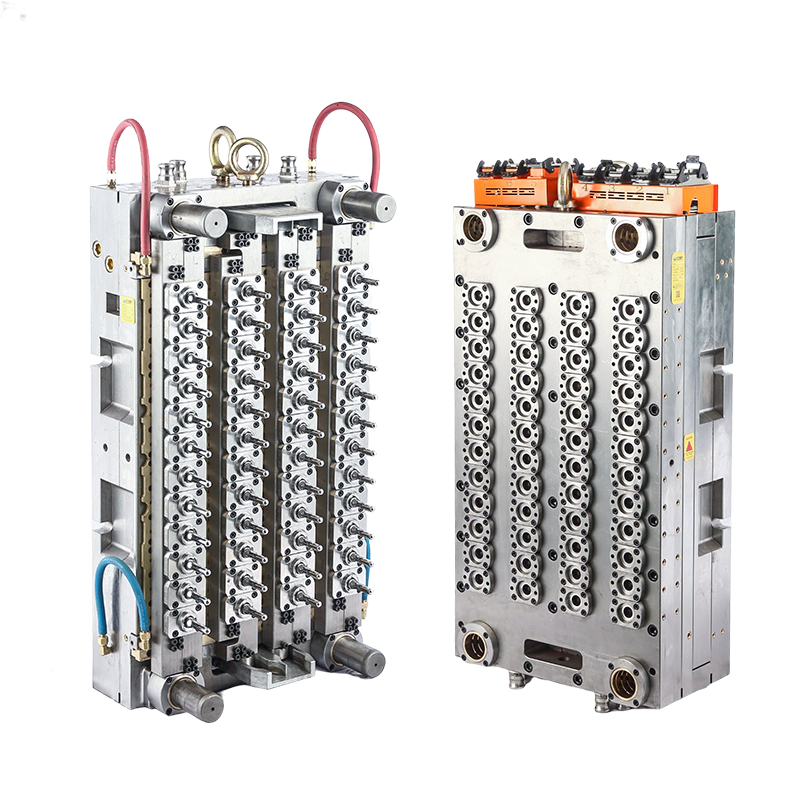

48 Cavity PET Preform Mould

| Product Name | 48 Cavity PET Preform mould |

| Core &Cavity Steel | S136,FS636,632 (Chinese Steel) ASSAB S136(Sweden) |

| Mould base | P20,4Cr13, Standard Mould Base |

| Steel hardness: | HRC32-35 for slider and stripper palte and other plates |

| HRC49-51 for core and cavity material. | |

| HRC49-51 for Neck ring and Lock ring | |

| Plastic material | PET resin |

| Cavity Number | 1x8, 1x16,1x24,1x32,1x48,1x64,1x72 |

| Injection System | Short tail, Long tail, Pin Valve gate |

| Ejector System | Stripper plate |

| Cycle Time | Based on preform weight |

| Delivery Time | 45-60 Days |

| Mould lifetime | At least 3million Shots |

| Warranty Time | One Year or 1million shots |

English

English русский

русский Español

Español عربى

عربى

+86-15157625901 / 13706572756

+86-15157625901 / 13706572756 info@suncomold.com

info@suncomold.com  No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China

No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China