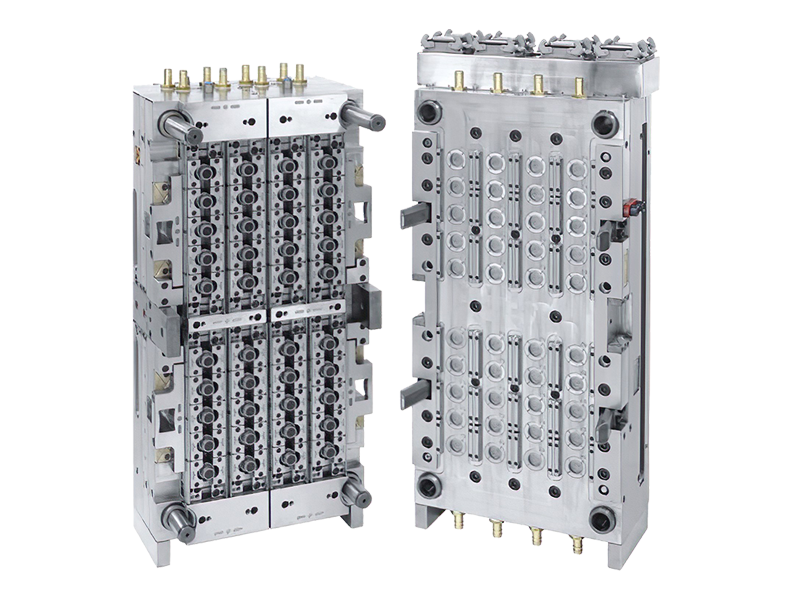

Glass Bottle Cap Molds, made out of quality and strength. These are perfect for creating a wide variety of things ranging from common household items and even appliances and automotive to commercial and other industrial products as well. These molded caps are fully customized and durable OEM products which are simply the perfect match for any kind of molding plant. Whether you're a glass bottle manufacturer looking to create a one of a kind cap for your products or an OEM repair center looking to upgrade your equipment you can count on these durable and custom caps. Plus, they can be colored any way you'd like, just ensure that they adhere to your exact specifications before ordering. In addition, because of their flexibility, they can be cut, drilled, glued, printed and many more!

Bottle Cap Molds can be manufactured to fit your exact mold opening requirements. This is why they are one of the most versatile types of cap for any manufacturing facility. They can also be printed with any graphic design you want and even sanded and colored just to name a few. These products can help you to create a better production line, safer products for the customer, and higher levels of productivity all because they are created with your specific mold opening in mind. This is called manufacturing efficiency and it's critical to the success of every business.

So, what can injection molding machines do for your company? Everything. Injection molding machines are a very important part of any bottle cap manufacturing system as they allow for the most efficient possible level of production throughout the entire production cycle. In other words, with a Bottle Cap mold, you can be sure that your caps will be ready to receive them when you need them, thus increasing your company's ability to process a larger volume of orders.

There are two basic ways to manufacture caps. The first involves creating molds from a hot molten steel mixture, which can take anywhere from several hours to a whole day. The second way to do it is with cold steel and then place-giving device and then a cooling system. Bottle caps are generally made with molds placed either on top of a rigid supporting structure or on a support itself. It all depends on the design of the product, the place-giving device used, the desired shape and many other factors.

In order to improve your ability to work with molds, injection mould manufacturers can greatly help you. An injection mould manufacturer can give you the advice and expertise you need to create an effective bottle cap mould. In fact, some manufacturers can even use their equipment to create the mold if you don't have the expertise to do so. This means you can place-giving device and then have the injection mould water fired up within a matter of minutes. In addition, these companies will use high quality raw materials and polymers, as well as ensuring the finished product meets industry and safety standards.

Once the injection mould is ready, the client simply needs to remove the cap and insert the moulding unit, which then presses the cap into one or more of the inserts. The client then needs to pull the cap away after which the cap core and the base of the cap come together, with each joining the base in the process. In the case of the latter, the core is manually pressed into the insert. In either case, the cap core will be removed once the core has been inserted into the insert, subsequently leaving a single stem component, which the cap fits into. The whole assembly then ejects out of the mould in a single smooth motion.

English

English русский

русский Español

Español عربى

عربى

+86-15157625901 / 13706572756

+86-15157625901 / 13706572756 info@suncomold.com

info@suncomold.com  No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China

No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China