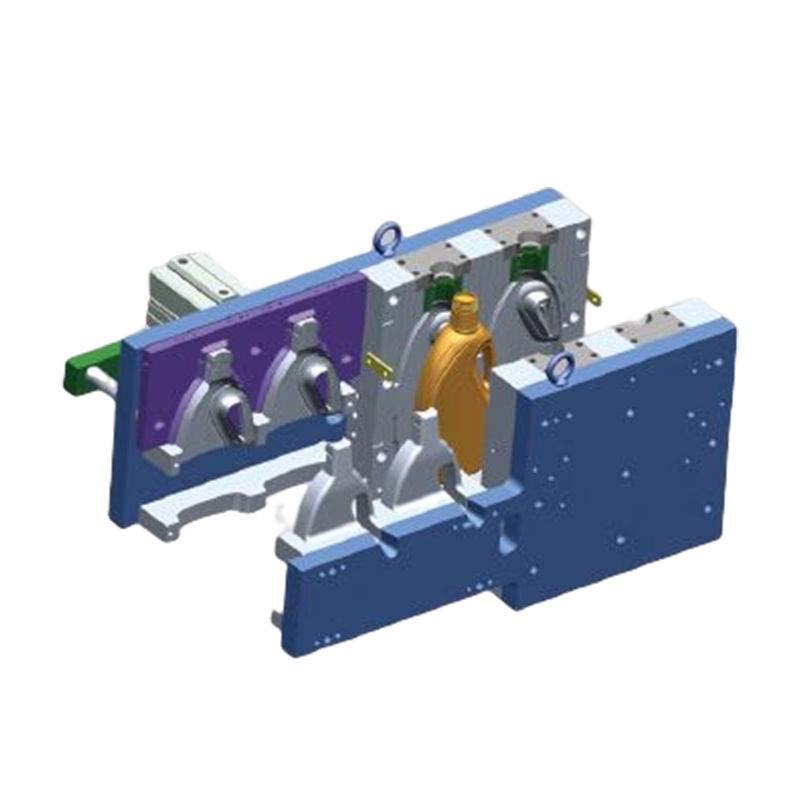

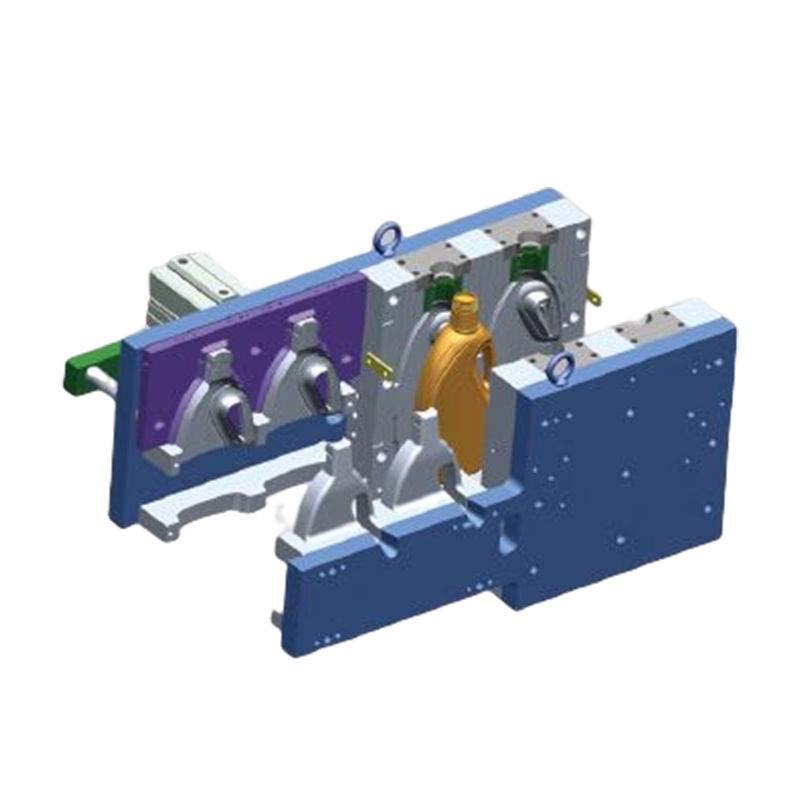

The Auto De-flash Bottle Mould system is a technological innovation that has revolutionized the bottle manufacturing industry by automating the removal of flash or excess material from molded bottles. This system offers numerous benefits in terms of efficiency and quality. We will explore how the implementation of an Auto De-flash Bottle Mould system improves the efficiency and quality of bottle manufacturing processes.

Increased Production Efficiency: Manual removal of flash from molded bottles is a time-consuming and labor-intensive process. The implementation of an Auto De-flash Bottle Mould system eliminates the need for manual intervention, leading to increased production efficiency. The system is designed to automatically detect and remove flash from the bottles as they are being molded. This automation reduces the cycle time and allows for continuous and uninterrupted production. By streamlining the de-flashing process, manufacturers can achieve higher production rates and meet customer demands more efficiently.

Consistent Flash Removal: The Auto De-flash Bottle Mould system ensures consistent and precise removal of flash from each molded bottle. It utilizes advanced sensors and robotic technology to identify and remove excess material with accuracy and uniformity. This level of consistency eliminates variations in the de-flashing process, resulting in bottles with consistent quality and aesthetics. Consistent flash removal also enhances the functionality and performance of the bottles, ensuring they meet the required specifications and standards.

Enhanced Quality Control: Flash on molded bottles not only affects the visual appearance but can also impact functionality and performance. The Auto De-flash Bottle Mould system plays a crucial role in quality control by eliminating flash and minimizing defects. By removing excess material, the system reduces the risk of uneven sealing surfaces, compromised structural integrity, or potential leakage issues. Improved quality control enhances customer satisfaction, reduces product returns, and strengthens the brand reputation of bottle manufacturers.

Cost Savings: The implementation of an Auto De-flash Bottle Mould system offers significant cost savings for bottle manufacturers. Firstly, the automation of the de-flashing process reduces labor costs associated with manual removal. Secondly, the system reduces material waste by precisely removing only the excess material, optimizing material usage. Additionally, the system improves overall production efficiency, allowing manufacturers to produce more bottles in a given timeframe. These cost savings contribute to increased profitability and a competitive edge in the market.

Worker Safety and Ergonomics: Manual de-flashing of bottles poses potential risks to workers, including repetitive strain injuries, cuts, or accidents. The Auto De-flash Bottle Mould system prioritizes worker safety by eliminating the need for manual intervention in the de-flashing process. Workers are relieved from physically demanding tasks, allowing them to focus on other important aspects of the production process. This promotes a safer and more ergonomic work environment, reducing the risk of injuries and improving overall employee well-being.

Flexibility and Customization: The Auto De-flash Bottle Mould system can be customized and adapted to different bottle designs, sizes, and materials. The system can be programmed to accommodate various mold configurations, enabling manufacturers to produce a wide range of bottles with different specifications. The flexibility of the system allows manufacturers to respond quickly to changing market demands and offer customized solutions to their customers.

In conclusion, the implementation of an Auto De-flash Bottle Mould system brings significant improvements in efficiency and quality to bottle manufacturing processes. The automation of flash removal increases production efficiency, ensures consistent quality, enhances quality control measures, and reduces costs. Moreover, the system prioritizes worker safety and offers flexibility in accommodating different bottle designs and customization requirements.

Auto De-flash Bottle Mould

Auto De-flash Bottle Mould

English

English русский

русский Español

Español عربى

عربى

+86-15157625901 / 13706572756

+86-15157625901 / 13706572756 info@suncomold.com

info@suncomold.com  No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China

No.2 Gongxin Avenue, Beicheng Street, Huangyan, Taizhou, Zhejiang, China