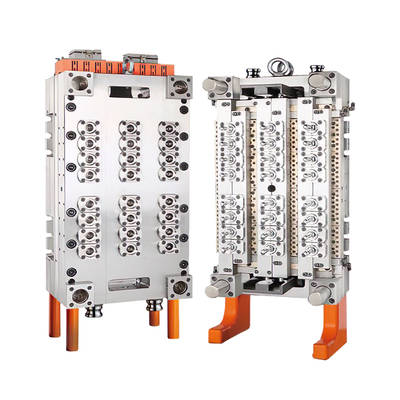

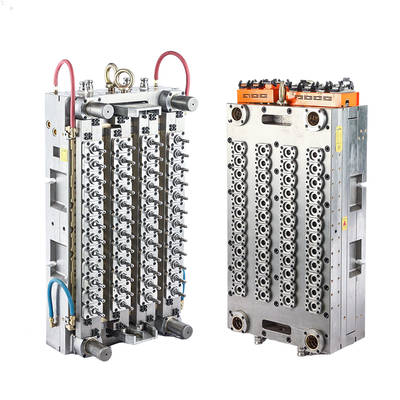

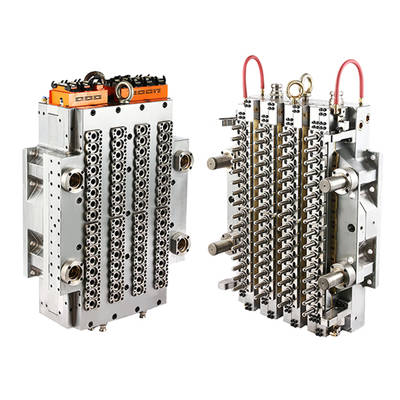

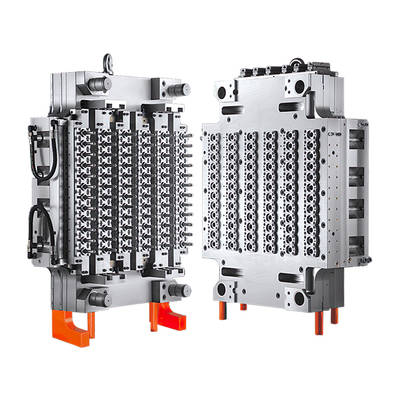

SUNCO MOULD, A PET preform mould manufacturer. With 10years of technology and manufacturing experience of PET preform mould. Our capabilities is offering the cavity number of PET molds ranges between 4 to 72.

To provide customers with products and services is our consistent quality. Developed on the premise of the latest technological developments, state-of-the-art preform mould construction has been designed in consultation with newest mould style. The technology improvement and upgraded design of mold structure have made the preform mould of SUNCO more durable, easier maintenance and more efficient production. SUNCO MOULD will serve you wholeheartedly and look forward to your down visit.

Standard PET preform mould features:

The cavity number of preform mould is from 4 to 96.

The hot runner system have three types, the best one with high price is pin valve gate hot runner, with a shut-off nozzle which is controlled by pneumatically-driven valve. The medium price is short tail preform mould with self-lock design, and preform have a short tail, but not need to cut it. The lowest price is long tail preform mould, the preform have a long tail, the tail have to by cut it by hand or by automatic cutting machine.

Cavity and core manufactured from highly conductive, tough and wear resistant steel, Thread splits manufactured from corrosion resistant steel. Stainless steel are applied to core parts, cavity parts and neck ring, it has imported steel ASSAB S136 and Chinese steel 632,636,S136 for your choice. And mould base can be stainless steel or common steel, mould steel can use P20, 4Cr13 or S136, such like the cavity plate, core plate, slider, stripper plate.

All stack components hardened to over 50HRC and nitrogen treatment. Nitriding is a cryogenic treatment, increases wear resistance and toughness beyond what is possible with a conventional hardening process. Resistant to plastic deformation and changes in dimensions.

Our design and benefits:

Core lock type stack design

- Thread splits are locked in position by lock rings before mould closing to minimize waear of thread split tapers on the cavity side for a long flash-less service life of thread splits.

- Preform collar is placed inside the thread splits to minimize clamping force requirement and resulting on the mould and clamping unit.

- Cores, core lock rings, thread splits, and cavity lock rings can be changed with the mould on the machine, for quick and easy servicing.

Modular cavity construction

- Replaceable cavity lock ring and gate inserts, the quick wear parts separated from cavity for inexpensive and easy replacement

Taizhou Shunke Moulding Co., Ltd is

China Preform Mold Manufacturers and

PET Preform Moulds Factory. We specialized in designing and manufacturing plastic cap mold, PET preform mold, blowing mold with our own mould factory. When we get samples or drawing of product, we always make all round analysis and inspection, such as moulding process feasibility, mould structure and movement feasibility, all the related plastic components matching situation, etc. We offer solution and custom make PET Preform Mould, other services.

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More