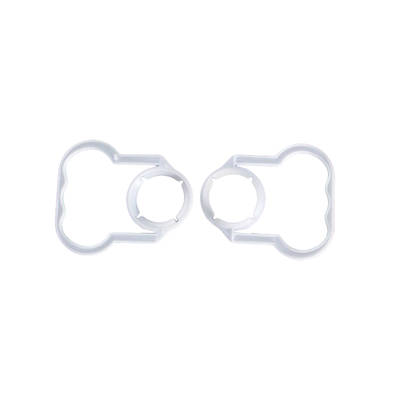

Bottle handle mould: SUNCO company is the famous Chinese plastic handle mould maker and we are export of making customized different kinds of plastic bottle handle mould.

We have more than 20 years experience to make different kinds of plastic handle mould including side handle plastic mould, neck handle plastic mould, 5 gallon handle plastic mould, two heads plastic handle mould, different neck or volume, we need to choose different design handle. The most important for the design of handle that we need to make the handle to match with bottle well. If the design of handle is not reasonable especially for the side handle design, when we blow, the bottle will be broken easily. The size of handle is big and we will give the suitable cavity NO. Based on client’s injection machine. Welcome for your kind inquiry.

The important for the Side handle design for mould: When client develop new mold for handle, first we need to consider that client has the ready bottle design or not, if client has it, we need to design the handle to match with the bottle well. Mostly, when client want to develop new bottle project, if it has the side handle design, then the handle design is very important. Because when we sell the bottle, different handle design will show the unique bottle design. Then customer know that this bottle with handle design is for your brand. We have our R&D team and when customer provide main idea, 1-2 days we can make 3D drawing for customer. And the principle to design the handle is that we must make enough weight capacity for handle when we lift the bottle. And also the hand to lift the bottle need to have enough space. But of course, when the design and requests is arrived, if we can make the weight as light as good that we can save the material cost.

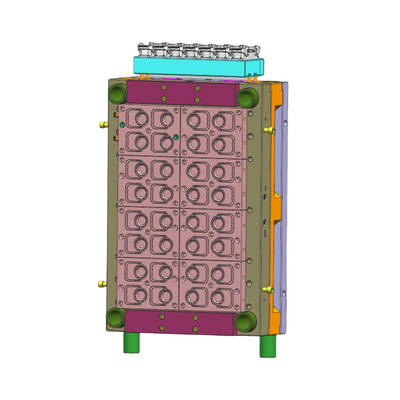

Side handle mould: when we confirm the handle design, we start to make the handle mould,

We will draw the suitable mold size to suit client’s injection machine. If multi cavity handle mould, we can make several inserts parts and in future, we can maintain with much easier. But in this way, the mold cost and mold size will be rising. Later, when we start to process the handle mould and the structure of plastic handle mould is not complicated and it only has two parts which core plate and cavity plate with parting line. It is similar as the commodity molds. And the longest processing time for handle mould is carving by carving machine. The processing cost is good and in this way, we must use good material such as S136 material for whole plate and the mold life could be guaranteed. All these parts, we can discuss with clients and in this way, you can see that the communication between client and foreign trader is very important and we have one team who engage in these parts for more than 10years. Welcome for your kind inquiry and we will have good pleasure business trip with us.

Taizhou Shunke Moulding Co., Ltd is

China Plastic Handle Mold Manufacturers and

Plastic Handle Mould Factory. We specialized in designing and manufacturing plastic cap mold, PET preform mold, blowing mold with our own mould factory. When we get samples or drawing of product, we always make all round analysis and inspection, such as moulding process feasibility, mould structure and movement feasibility, all the related plastic components matching situation, etc. We offer solution and custom make Bottle Handle Mould, other services.

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More